|

|

|

|

|

|

|

|

|

| 400 HP Garder-Denver Retrofit - Before and After |

|

| click to enlarge |

| Gardner-Denver Retrofit - Before and After |

|

| click to enlarge |

|

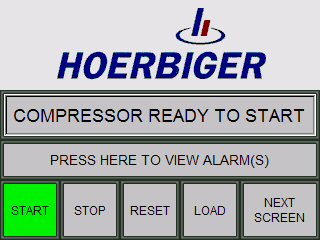

| Compressor Soft Start and Controllers |

|

| click to enlarge |

|

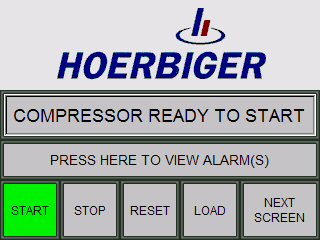

| Compressor Soft Start Retrofits |

|

| click to enlarge |

|

|

|

High-Pressure Compressor

Sequencer Systems |

|

| click to enlarge |

|

| Ethernet/IP High-Pressure Compressor Sequencer |

|

| click to enlarge |

|

| Custom Compressor Control Systems - Private Label |

|

|

|

One of the easiest and most effective ways to reduce your plant's operational expenses

is to have a good control and capacity management system for your air compressors. TOO MANY OF YOUR HARD EARNED DOLLARS ARE WASTED ON:

|

|

|

Compressors continuously running half-loaded due to mismatched loading setpoints |

|

|

Compressors running unloaded for hours during a scheduled preventative maintenance shift |

|

|

Compressors running "in case" you may need the air it provides |

|

|

Increased maintenance costs due to no-load and half-load cylinder super heating |

|

|

Reduced compression ring, wear ring and intake/discharge valve life |

|

|

Air leaks from broken air lines, fittings and poorly connected devices |

CONNELL INDUSTRIES HAS THE SOLUTION

All of the above items reduce your overall

operational efficiencies by a significant margin, and once they have been wasted they can never be regained! What can you

do to stop the waste and invest that money back into your company?

WE CUSTOM DESIGN AND MANUFACTURE CUSTOM COMPRESSOR CONTROL

SYSTEMS THAT WILL:

- Replace your obsolete compressor

controls with a network based PLC control system

We use all of the major

programmable logic controller manufacturers for our control systems. This ensures that we will have a PLC system to match

your plant's PLC manufacturer preference. Thus reducing maintenance training and support equipment expenses for software,

cables and manuals.

.. - Provide

overall compressor system capacity controls based upon your actual air demand

Your

Connell Industries compressor capacity system will be able match the output of compressed air to your actual plant's compressed

air demand. Your compressors will no longer idle away needlessly or half-loaded, burning through hundreds of your hard earned

dollars by the hour. In addition, additional savings can be realized by lower cooling tower energy demands from a reduced

compressor load.

.. - Lower

your overall compressor system's maintenance and utility costs

By only

running the compressors you need, when you need them your overall maintenance costs will be reduced. Wear and tear on the

compressor compression and rider rings, intake and discharge valves and valve actuators are all significantly reduced.

Connell Industries will evaluate your current air compressor control systems to

help you make an informed decision on improving the overall efficiency of your entire air compressor system.

We can develop

a control scheme based upon the individual needs of your facility and implement a solution in as little as (4) weeks! Think

about that... You can be saving literally thousands of dollars a month in utility costs in less than a month!

In today's fast-paced manufacturing

environment, every second counts. Let Connell Industries help get your air compressor systems under control

and in top running condition, call us today at (877) 926-6635. Or if you'd prefer, you can Email us at connell@connell-ind.com. Premier control system integrators - Connell Industries

- provide total control systems engineering from basic programming skills to overall project management.

|

|